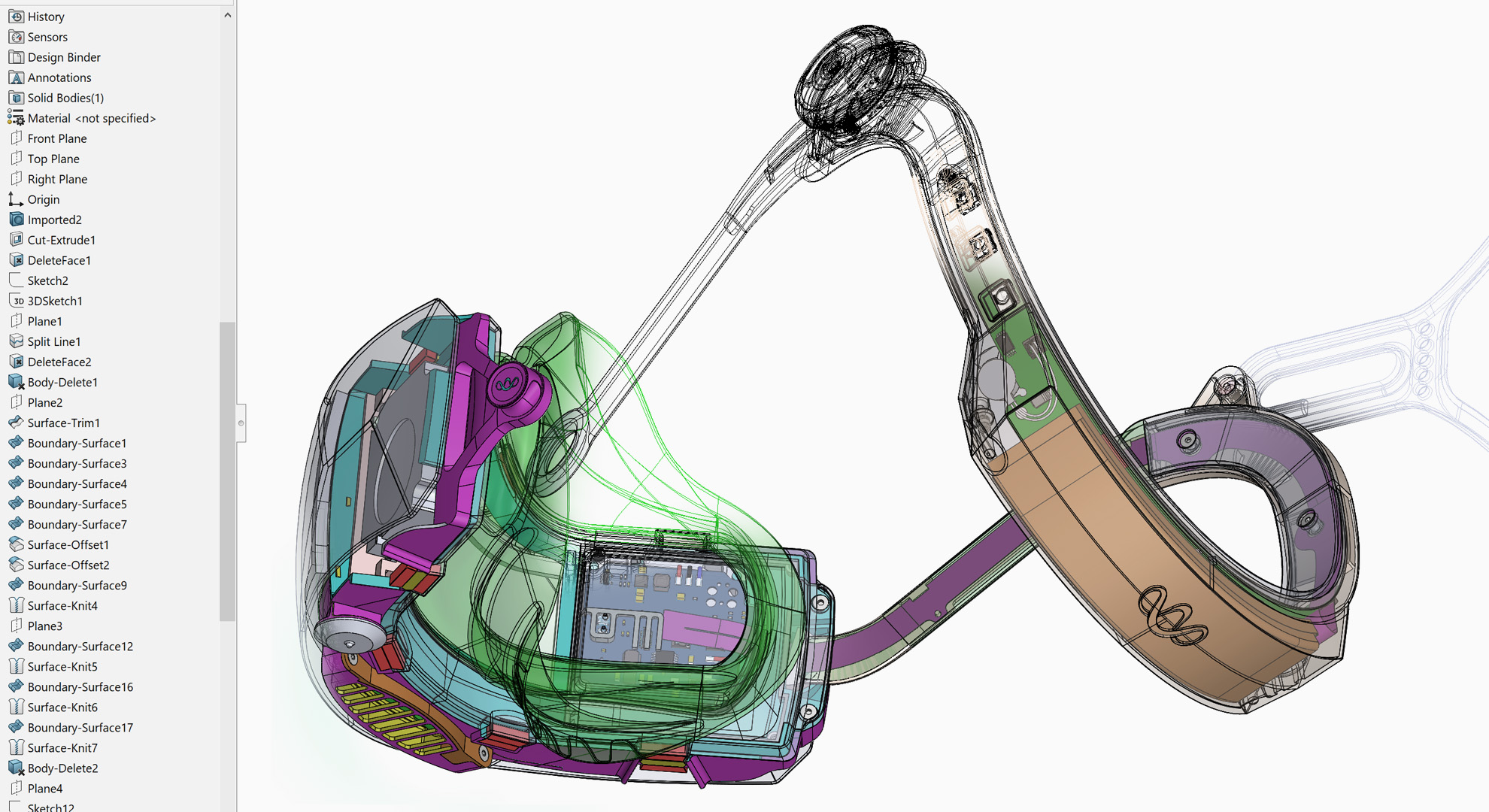

4design engineers every product in 3D CAD to optimise mechanics, maximise productivity and meet stringent regulatory standards.

Engineering is where every aspect of the product is resolved. How these details are implemented will determine the products performance, aesthetics, manufacturability and ultimate commercial success.

We run multiple 3D CAD platforms to ensure we have the flexibility to choose the best tool for your product.

Our engineering team is an experienced and accomplished group of very clever implementors, with significant experience across every manufacturing process

4design has engineered a number of products to comply with the global ingress protection (IP rating) standards for dust and water protection. Developing IP rated products relies on an understanding of the precise engineering details to meet each rating. Over engineering can increase the BOM cost, under engineering can lead to product failure, so getting the balance right is absolutely key.

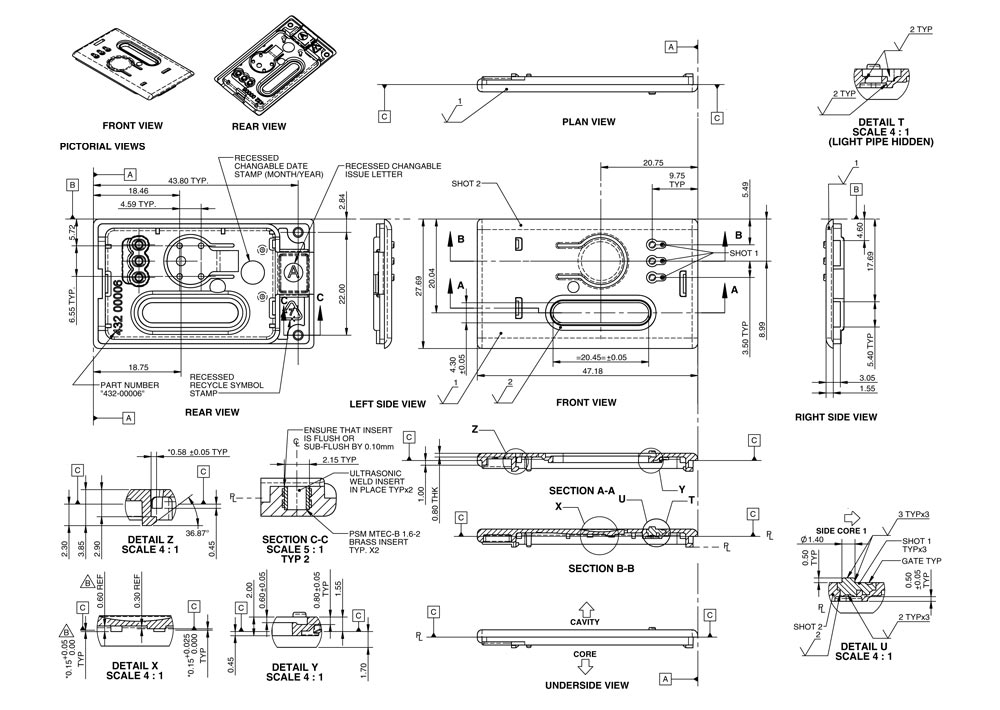

All products and their components require concise 2D CAD specification to support 3D production files. Thorough documentation ensures parts and assemblies are made as per intent and within acceptable quality limits. Dimensions, finishes, materials and assembly processes must all be accurately documented.

We have over 50 years of experience at the ‘coal face’ of production. We understand the requirements when specifying parts to suit each and every manufacturing process. From injection moulding plastics, aluminium extrusions to die castings; the design guidelines around each process are very different and critical to achieving a repeatable, high quality part.

We run real-time systems for clear and traceable part updates, revision controls and issue tracking

4DESIGN’s experience and knowledge with Electrical Engineering allow us to push the boundaries of whats possible with today’s electronics. This allows us to hold true to our I.D. vision and our clients requirements while fully supporting our EE partners/production vendors for seamless product development.

Using our established vetted manufacturing partners we offer our clients a wide choice of potential vendors around the globe that have world leading technology at competitive pricing.

- Electronic design and configuration.

- Prototyping and POC.

- Production electronic sourcing.

- BOM and Schematics.

- Overseeing Gerber file production.

- Manage testing/certification.

- Global EE partners for PVT to MP.

- Testing/certification.

- Assembly & QC.

These skills combined with our in-house UI design allow for meaningful physical and digital experiences for everyday uses.

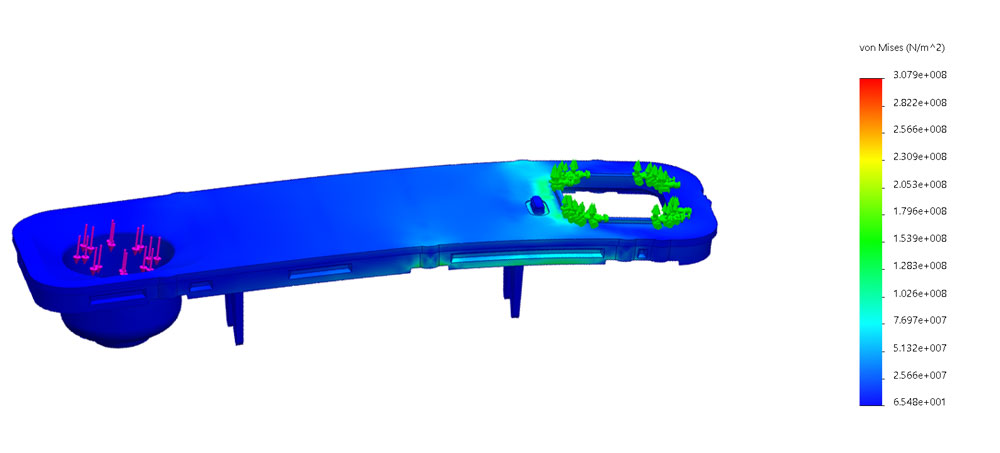

Finite Element Analysis is an important tool used to preempt issues with respect to a components structural integrity. We can simulate forces applied to a part or assembly in advance to understand how the part deforms under certain load conditions based on a specific material. This enables us to identify the weak areas through mechanical stress analysis, fatigue and or vibration to mitigate the risks early in the process.

Thermal management can be a key consideration, previous experience combined with the latest thermal CAD analysis can predict product performance and improve functionality and performance.

Our thermal analysis services will help with the selection of the materials, processes and technologies, optimisation of the product’s weight, positioning of components and optimisation of enclosures to encourage airflow or heatsinks and fans for active cooling.