Prototyping is essential to validating a product and provides a powerful insight into all levels of evaluation. We use prototypes early in development and have skills to produce simple form studies to fully functioning prototypes.

4design has a well established team of partners to simulate parts to suit every manufacturing process. We offer a high quality and comprehensive prototyping service to compliment every project.

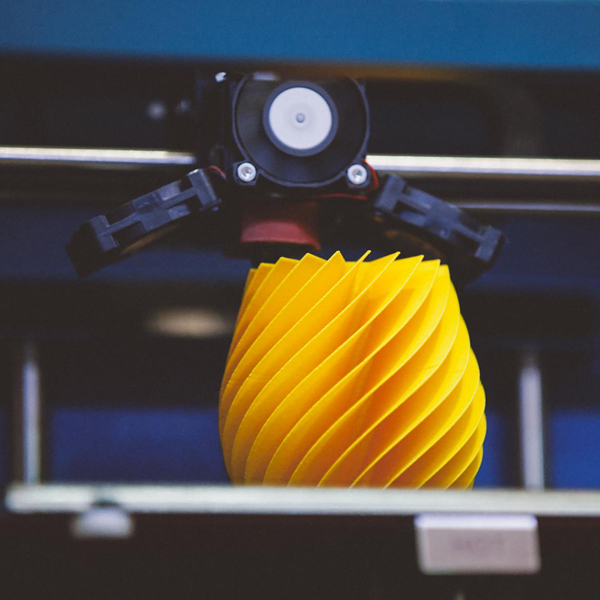

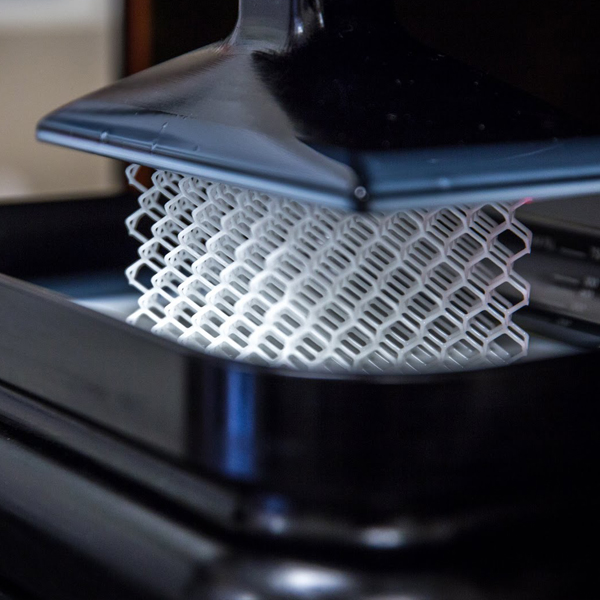

3D printing technologies are constantly changing and improving, 4design have strategic partnerships with some of the worlds most advanced 3D printing technology innovators which compliment our capabilities and allow us far reaching and fast delivery of the most advanced 3D prints in the market.

Our services include:

- Continuous Liquid Interface Production (CLIP)

- Selective Laser Sintering (SLS)

- Stereolithography (SLA)

- Composite multicolor

- Polyjet Printing

- Multi Jet Fusion

- Direct Metal Laser Sintering (DMLS, SLM, Wax Casting)

- Titanium additive manufacturing (EBM)

From the smallest of medical products to large, metal structures, 4design’s fully functioning prototypes are a vital step to bringing your innovation to life.

Made from production simulants, our functional prototypes allow you to test the properties of the product or part prior to production in most time and cost-efficient way.

Our fully functional prototypes can also be used for compliance testing and legislative approvals prior to full scale manufacture or for you to secure your next crowdfunding, grant or investment funding.

Assessment of product features, ergonomics, size and proportion is fundamental to effective product development. The power of tangible and tactile visual representations of products throughout the product design process will improve the project outcome and ultimately the success of the product.

We employ traditional and contemporary product design techniques to develop visual models. These are made in-house by our industrial design team to ensure effective translation from concept to model. These can range from simple form studies through to highly detailed visually accurate models.

We’re experienced makers! We can produce anything from a one off prototype to high volumes.

Our point of difference is our experience and knowledge not just in design but in the manufacture and supply of high-quality custom components. We understand high and low volume prototyping and can advise on the most appropriate production methods.

4design are low volume production specialists in New Zealand across a range of different manufacturing processes. We are experts at producing parts in the 10 to 1000 quantity range, striking the perfect balance between producing parts at a competitive pricepoint with the highest quality.

We also offer an optimised supply service – a key difference between 4design and other New Zealand Industrial Design Consultancies